We are a Panamanian company specializing in non-destructive testing and thickness measurement for vessels and industrial projects. Our services ensure precision, safety, and reliability in every inspection.

To provide our customers with first-class quality control and non-destructive testing services that ensure the integrity and reliability of their projects. We are committed to delivering precise, effective solutions that guarantee the safety and efficiency of their operations.

We aspire to be recognized worldwide as a leading and prestigious company in the field of non‑destructive testing, setting the highest standards of quality and excellence. We aim to be our clients’ preferred choice, delivering superior results efficiently, reliably, and safely, supported by a highly trained and committed team.

At our company, we have a multidisciplinary team of highly trained professionals specializing in non-destructive testing (NDT), committed to excellence, safety, and innovation. Each team member brings a unique combination of technical expertise, specialized certifications, and a genuine passion for their work, allowing us to deliver accurate, reliable, and tailored solutions to our clients. We operate in a collaborative environment where respect, responsibility, and continuous improvement are core values. Our goal is to exceed expectations, ensure the integrity of the materials we inspect, and build long-term relationships based on trust and results.

Non-Destructive Testing (NDT) refers to a range of techniques used to evaluate the properties, integrity, and potential defects of materials, components, or structures without causing damage.

Visual Inspection (VT) is the most fundamental, cost-effective, and widely used non-destructive testing method. It consists of directly observing a material, component, or structure to identify visible surface defects such as cracks, corrosion, deformation, or welding irregularities.

Liquid Penetrant Testing (PT) is one of the most widely used non-destructive testing methods for detecting surface discontinuities such as cracks, porosity, undercuts, and other defects in non-porous solid materials.

Magnetic Particle Testing (MT) is a non-destructive testing (NDT) method used to detect primarily linear discontinuities located at or near the surface of ferromagnetic components and structures. This method is specifically designed to reveal cracks.

Ultrasonic Testing (UT) is one of the most widely used methods for inspecting materials and components due to its ability to detect internal defects without damaging the part. This technique relies on the propagation of ultrasonic waves (high-frequency sound) through a material to detect discontinuities, measure thickness, and assess mechanical properties.

Vacuum Box Testing (VBT) is a non-destructive testing (NDT) method used to verify the hermeticity and structural integrity of various components. This test is essential in applications where the inspected structures must be completely sealed to prevent the leakage of air, liquids, or gases.

Hardness testing is a mechanical test used to measure a material’s resistance to deformation, indentation, or scratching. In simple terms, it evaluates how hard a material is, which directly relates to its ability to resist wear, abrasion, and permanent deformation.

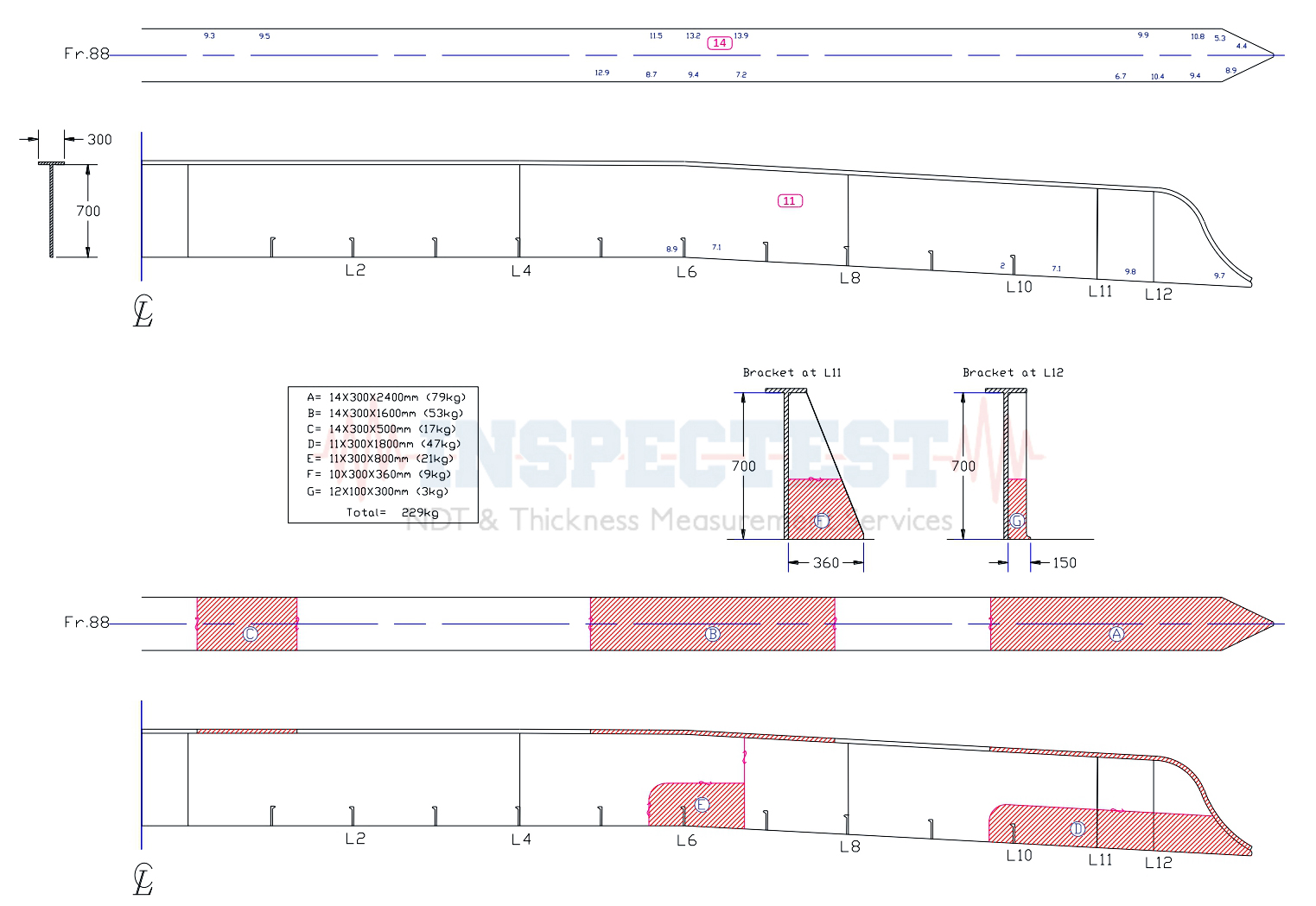

Ultrasonic Thickness Measurement is a highly important technique in the naval industry to ensure the safety and structural integrity of ships. Vessels, especially those exposed to harsh marine conditions, can experience corrosion and wear on their hulls and other metal components. Precise thickness measurement is critical for preventing structural failures that could compromise the safety of the ship.

We provide UTM services in full compliance with leading classification societies, including DNV, ABS, Lloyd’s Register, Bureau Veritas, RINA, and NKK.

Over time, corrosion, erosion, and material fatigue can reduce the thickness of structural components, posing serious safety and operational risks. Classification societies require regular thickness inspections to:

If you own a vessel or manage a fleet, you know that prevention is key. Ultrasonic Thickness Measurement (UTM) provides a clear and accurate picture of the condition of your ship’s hull, tanks, and steel structures—without requiring involvement from a classification society.

Ideal for internal inspections, maintenance planning, or assessing a vessel’s condition before making major decisions, our UTM service is a smart and reliable tool for responsible owners.

Why Perform UTM for Your Own Records?

Before sending your vessel to dry dock for steel renewal or major repairs, an accurate assessment of the existing steel thickness is essential. Our Ultrasonic Thickness Measurement (UTM) service provides reliable and precise data to help you plan maintenance effectively and control repair costs.

Why Perform UTM Before Dry Docking?

In our Magazines and News section, we share the latest developments, achievements, and updates that guide the direction of our company and the industry in which we operate.

+507 6394-7472

+507 6910-9938

+507 6580-3524

+507 6860-3100